Top Quality Prefabricated Steel Vehicle Inspection Pits

Vehicle Inspection Pits UK Ltd specialises in manufacturing top quality prefabricated steel vehicle inspection pits of any size for a wide range of applications and vehicle types including HGV’s, coaches, buses & cars in order to provide a durable maintenance free solution that is tailored to meet our customers needs and requirements using only the highest quality steel, extras and accessories at very competitive prices nationwide.

- Hardwearing low maintenance

- Water tight clean work space

- Improved working conditions

- Safe working environment

- Work above and below vehicle

- Easy installation less disruption

- No staining or concrete spalling

We can design and fabricate a workshop inspection pit of any size and for any application, all our pits are manufactured from high quality mild steel plate to exacting standards in our fully equipped fabrication workshop by our highly skilled fabricators/welders to form a permanent and continuous water tight seal between the floor and walls of the pit.

Each inspection pit comes with a set of full width folded chequer plate stairs at one end and a set of ladders at the opposite end plus all the necessary structural engineers calculations, 10 year guarantee on manufacturing defects, method statements, risk assessments & concrete specification for installation, providing the option to use a local builder/ground worker to install the pit or call us for a quote.

Through our direct connections with manufacturers and suppliers we are able provide the highest quality materials and products available at very competitive prices and our flexibility and strong focus on customer service has lead to many satisfied customers and repeat business, you can find more detailed information about our products & services and the wide range of extras & accessories that we provide below.

Enquiries are welcome from garage equipment supplies sales representatives and garage & workshop owners, customers are also welcome to visit our manufacturing facility in Lytham St Annes to inspect the quality of work and high quality finish of our workshop pits or you can just contact us for a very competitive, no obligation quotation

- Inspection Pit

- Truck Pit

- Lorry Pit

- Wagon Pit

- Tractor Pit

- Tug Pit

- Bus Pit

- Van Pit

- Steel Pit

- Workshop Pit

- MOT Pit

- MOT Lane

- ATF Pit

- ATF Lane

- Commercial Pit

- Service Pit

- Garage Pit

- Grease Pit

- Galvanised Wash Down Pit

- Galvanised Wash Ramps

- Garage Equipment

- Play Detectors

- Shaker Plate Trays

- Turning Plate Trays

- Pit Jacks

- Jacking Beam

- Steel Fabrication

- Finance Options Available

VIP UK Ltd – Products & Services

Vehicle Inspection Pits UK Ltd is a local business that specialises in manufacturing top quality prefabricated steel vehicle inspection pits of any size for a wide range of applications and vehicle types including HGV’s, coaches, buses & cars in order to provide a durable maintenance free solution that is tailored to meet the customers needs and requirements using only the highest quality steel and accessories at very competitive prices.

We have the experience and technical skills to design a workshop inspection pit of any size or style and each pit is designed quite literally from the ground upwards. After taking into account the ground conditions, load bearing calculations and the proposed application for the pit to meet our customers needs and requirements. From a simple design for the budding DIY mechanic in their home garage through to commercial workshop pits for ATF’s (Authorised Testing Facilities) and MOT stations for Class 4, 5, 7 and HGVs that meet DVSA/VOSA standards, we can design a solution that is tailored to meet your requirements.

Our workshop inspection pits are manufactured from high quality mild steel plate to exacting standards in our fully equipped fabrication workshop, the walls running the length of the pit have a folded recess just below the top that increases the strength of the pit wall and it also provides space to easily and neatly accommodate air lines, strip lighting and power sockets that you may require either at the time of manufacture or the extras can be retrofitted at a later date if required.

The floor of the workshop inspection pit is manufactured from high quality mild steel chequer plate with an anti slip finish and when the pit floor is formed the sides of the floor are folded upwards in order to further increase the side wall strength of the pit and the floor is then MIG welded to the walls of the pit to form a permanent and continuous water tight seal between the floor and walls of the inspection pit.

Along the top of the side walls that run the whole length of the workshop inspection pit, heavy duty parallel faced channels are fitted for a jacking beam to run in and these also increase the side wall and overall strength and integrity of the pit, all our workshop pits are manufactured to our exacting standards and are seam welded by our highly skilled and time served fabricators/welders ensuring our pits are water tight and leak free.

The inspection pits also have vertical gussets (high quality 6mm mild steel plate) that are MIG welded on to the outside of the walls which again increases the side wall strength and overall integrity of the inspection pit and steel reinforcing bars are also welded to the outside face of the pit walls in order to firmly fix and anchor the inspection pit in the concrete under the workshop or garage floor.

Each inspection pit also comes with a set of full width folded chequer plate stairs at one end of the pit that are removable so that the space beneath them can be easily utilised for storage and it also comes with a set of ladders at the opposite end. The stairs can also be made in an "L" shape configuration and the stairs can also be fitted at both ends of the inspection pit if required to provide easy access.

In the final stage of the manufacturing process two protective coats of Zinc Phosphate Primer finish are applied to the external walls of the pit in order to prevent corrosion and meet DVSA/VOSA specifications. Then a coat of primer along with two coats of white gloss finish is applied to the internal walls of the pit using the environmentally friendly electrostatic spraying technique. Then a durable and hard wearing black paint is applied to the floor of the pit in order to provide maximum protection and top quality finish that will last many years.

Quality Control And Delivery

Throughout the manufacturing process we perform rigorous quality control checks in order to ensure that each pit meets our exacting standards and health & safety requirements, there is no limit on the actual size or length of the pits we can manufacture in our fully equipped fabrication workshop each pit can be fabricated in sections which can then be easily transported and the sections welded together in situ on–site.

All of our prefabricated workshop pits are supplied complete with all of the necessary structural engineers calculations, method statements, risk assessments and concrete specification for installation allowing you the option of using a local builder/ground worker for installation or you can contact us for a no obligation quote for installation, you can find all of our contact details here

We have a large yard outside our fabrication workshop for loading and unloading that can easily accommodate an articulated lorry with plenty of room to turn around and we also have good access to the local road & motorway network and our close ties to local transport & haulage companies allow us to provide delivery and transportation services at very competitive prices.

Customers are welcome to arrange to collect and transport completed pits directly from our premises or contact us for a competitive delivery quote

Pit Extras and Accessories

Vehicle Inspection Pits UK Ltd can provide a wide range of extras and accessories for workshop vehicle inspection pits to suite all types, sizes and applications which can either be installed during the manufacturing or installation process or they can be retrofitted at a later date if required.

Pit Jacks

Heavy duty air over hydraulic or manually operated pit jacks to suit any type of application to meet the customers requirements.

Lighting

Zone 1 or Zone 2 ATEX strip lighting/sockets as required by HSE for hazardous areas. IP66 lighting with strong durable casings pre-wired with brass ATEX glands and steel armoured cable.

Air Lines

High quality galvanised steel airlines with quick release couplings for easy use of hand tools/pit jacks within the pit.

Sumps

Sumps for submersible pumps to remove wash down water and sumps for brake testers that are manufactured from high quality steel to meet the customers requirements.

Waste Oil Tanks

We can provide waste oil tanks that meet the customers requirements whether this be a portable or static tank we can provide a solution that will meet the customers requirements.

Pit Covers

Pit covers manufactured from high quality steel square section gratings that combine great strength with a light weight structure that provides good non–slip properties for pedestrian traffic within the workshop or garage.

Pit Trays

High quality steel trays for for shaker/turning plates can be manufactured from high quality mild steel to meet the customers requirements.

Pit Cupboards, Tunnels

We can manufacture workshop pit side storage cupboards, connecting tunnels and side access tunnels to stairs or ladder for DVSA/VOSA designated sites. The stair treads can be removable providing extra storage space for vital equipment below keeping the pit uncluttered.

Work Platforms

Slide along work platforms to provide that extra bit of height when working in the pit can be manufactured to meet the customers specific requirements.

Enquiries are welcome from garage equipment supplies sales representatives and garage & workshop owners, customers are also welcome to visit our manufacturing facility in Lytham St Annes to inspect the quality of work and high quality finish of our workshop pits or you can just contact us for a very competitive, no obligation quotation

Information About Vehicle Inspection Pits UK Ltd

Vehicle Inspection Pits UK Ltd is a family business that specialises in manufacturing steel vehicle inspection pits, the business is located in Lytham St Annes on the Fylde coast with good access to the local transport network and nearby towns & cities. The business was formed in January 2012 by the owner Dean Fox who is highly skilled, fully qualified and time served plant fitter and welder with over 24 years experience working in the engineering, metal fabrication, transport and agricultural industries.

Over the years Dean has worked for a broad range companies of all sizes as a time served and fully qualified fitter & welder in both the private & public sectors and along with his strong rural background they provide many years of valuable practical experience and the technical knowledge & skills required to set up and then run and develop the business successfully.

During the first year VIP UK Ltd gained an outstanding reputation for the quality of their work, dependability and strong focus on "customer care" and the exceptional "after sales" service, which has lead to long term relationships and repeat business with many satisfied customers.

VIP UK Ltd has a very strong commitment to health and safety compliance and the continued training and the development of our highly motivated, skilled and experienced workforce which consists fully qualified and time served welders/fabricators who all hold a current CSCS certificate and appropriate qualifications.

Vehicle Inspection Pits UK Ltd Recent Projects Gallery

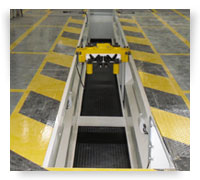

Here are some images from projects that Vehicle Inspection Pits UK Ltd have recently completed.

Vehicle Inspection Pits UK Ltd Contact Details

If you would like a quotation or more information about the products and services that we provide or you would like to make a general enquiry or just ask a question, please feel free to get in touch using the contact details provided below, using the method that you find the most convenient. Such as telephone or email using either an email client such as Outlook, Outlook Express, Windows Live Mail etc. Or by using the Mail Form to send an email message and the great thing about the Mail Form is that you can send us an email even if you do not have an email account, but please remember to enter your telephone number in the field in the form or in the message so that we can reply and call you.

Mobile

Please call between 8:30am to 5:30pm

From Monday – Saturday

07780 – 645526

If you would like to use an email client (software)

such as (Outlook, Outlook Express etc) to send

an email please use the link below.

Click to send an email Enquiry

Postal Address

Vehicle Inspection Pits UK Ltd

Queensway industrial estate

Snowdon Road

Lytham, St Annes

Lancashire

FY8 3DP

Travel Directions

If you are not sure where we are or how to find us

you can find travel directions & larger map here

Privacy Policy

Your privacy is very important to us here at Vehicle Inspection Pits UK Ltd and we are committed to safeguarding the privacy of the visitors to our web site and any personal data that is submitted on this web site will only be used to deal with enquiries and complaints relating to this web site and/or the services or products provided by this web site.

We will not provide your personal information to any third parties for the purpose of direct marketing.